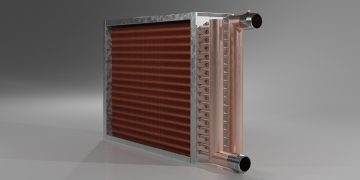

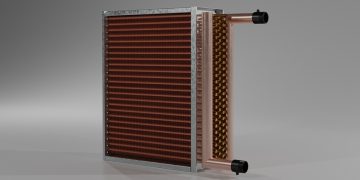

Cleanable Coils

These fluid coils feature removable brass plugs on the tube ends that allow access to the interior of the coil for cleaning. They are typically used in environments where sediment or foreign materials may accumulate within the coil. Individual tube access allows for simple inspection and isolated cleaning, which can return the coils to like new performance levels.

Plugs can be located on the supply header end (J coils), on the opposite side of the header (K coils) or on both ends to allow straight-through cleaning (X coils). Our J, K and X cleanable coils can be used in high-pressure applications and can be ASME “U” stamped for extreme environments.

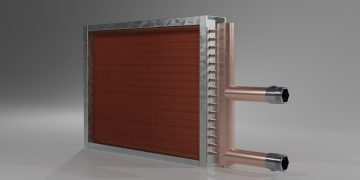

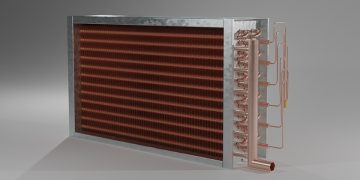

Coils with Removable Box Headers

Another fluid coil option that allows access to the interior of the coil for cleaning, our coils with removable box headers are used in low-pressure applications. The removable box is ideal for high-sediment fluid environments, such as river or lake water. Removing the headers exposes all of the tubes for easy inspection or cleaning.

We offer three removable box header locations: on the supply header end (Q coils), on the fluid-return end of the coil (Y coils), or on both ends of the coil to allow straight-through cleaning (R coils).

Removable Coil Modules (RCM)

Our Removable Coil Module is a direct replacement coil section for existing air handling units. The RCM can simplify coil replacement while adding new coil supports and a stainless steel drain pan to existing units. RCMs are available in custom sizes ranging from approximately 2- 60 square feet of coil face area. Features include:

- Galvanized or stainless steel cabinets, optional painted exterior

- Custom heating or cooling coils, including steam and water coil combinations

- Integrated lifting lugs

- Full-length stainless steel drain pan with IAQ slope

- Coils removable from either side of cabinet

- Single or double wall construction

- Choice or 1″ or 2″ insulation

- Optional integrated filter section

Split Core Coils

Our split core coil is an optional feature that allows nearly any coil we manufacture to be divided into smaller sections to ease installation in limited space applications. The coil is split in the core area with divider plates and re-assembled on-site for a permanent installation. The coil sections can fit through standard openings in a building and in tight spaces, avoiding costly removal of walls or equipment to install a full-size coil. Split core coil features include:

- Allows direct replacement of long-finned length coils with minimal performance loss

- A coil can be divided into several sections if required

- Existing AHU or ducts can be used with little or no modifications

- Existing piping can be used without modification in most cases

- Coil core is leak tested at the factory prior to shipment

- A unique sealant is used to seal the assembled coil without plugging tubes

Humidity Control Coils (HCC)

Our Humidity Control Coils solve a common problem in hospitals and other critical environments: excess humidity and condensate collecting on and ruining expensive HEPA and ULPA filters. This single cooling coil recirculates the warm fluid leaving the coil to, in turn, heat and desaturate the air exiting the coil. It requires just one supply and one return header, which saves the significant costs involved with plumbing hot water or steam to a reheat coil.

HCC advantages include:

- Much more cost effective than the traditional solution of using both a cooling coil and separate heating coil

- Use of a common frame and single inlet and outlet greatly reduce complexities and installation costs

- Re-heat circuits on the air exit side of the coil reduce humidity and minimize carryover

- Intermediate drain pans, compliant with indoor air quality standards, further eliminate condensate management problems

More Products

Related News

Contact

For any further information or to request a quote