Coil Product Showcase

As a custom coil manufacturer, every day brings a new opportunity to design and build a heating or cooling coil to meet the individual needs and challenges of a specific application.

Pictured below are a few examples of the types of unique coils we manufacturer day in and day out at Marlo – in a range of sizes, types, configurations and materials. Click the thumbnails below to see the full image.

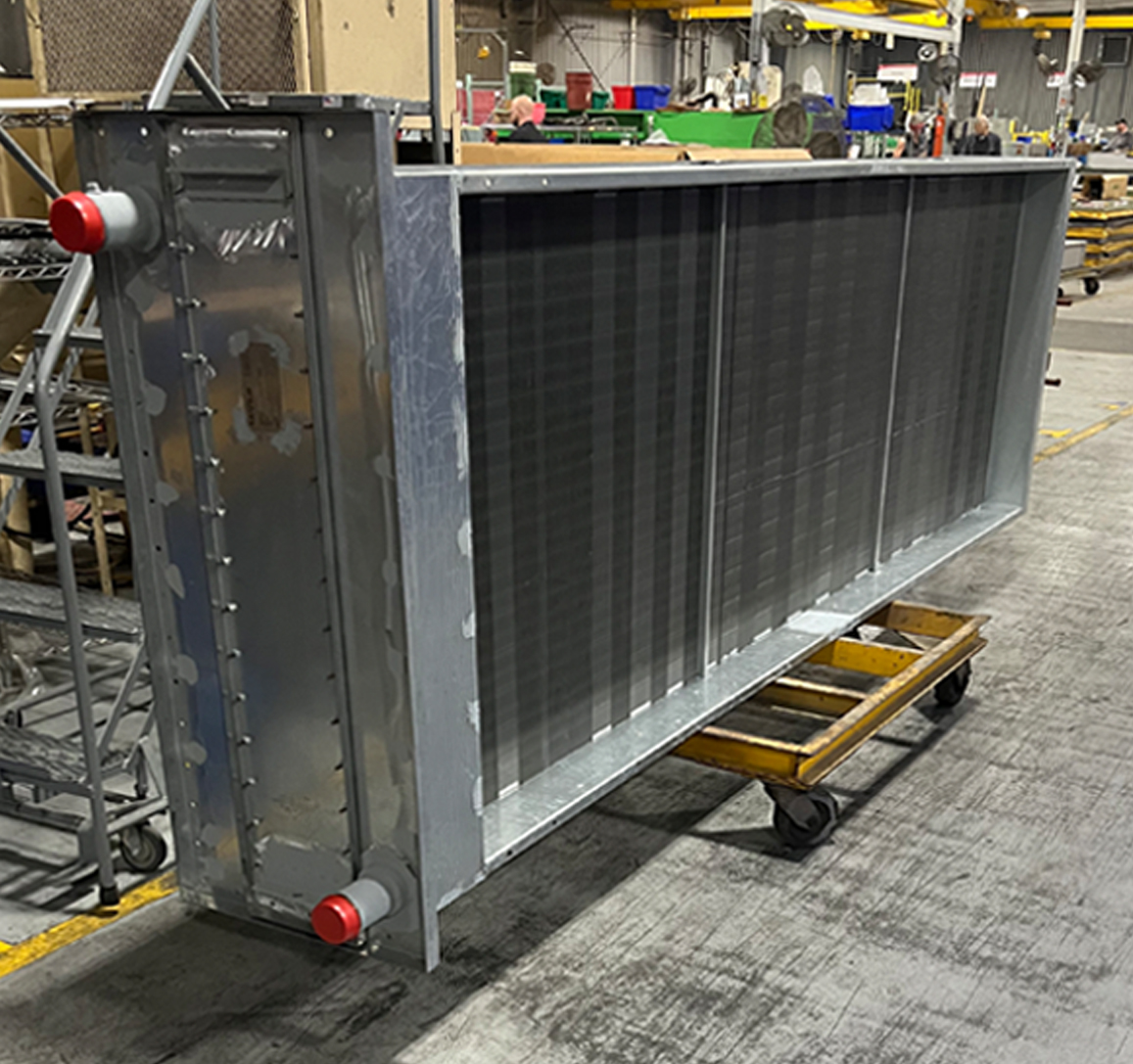

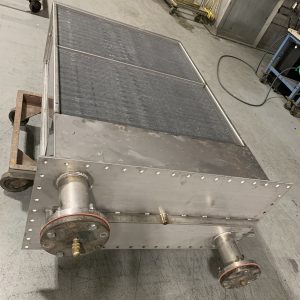

Airtight Housing

This industrial process coil was designed to slide into a housing and be sealed from the surrounding air by an airtight closure panel, stopping process side gas from escaping into the ambient air around the housing.

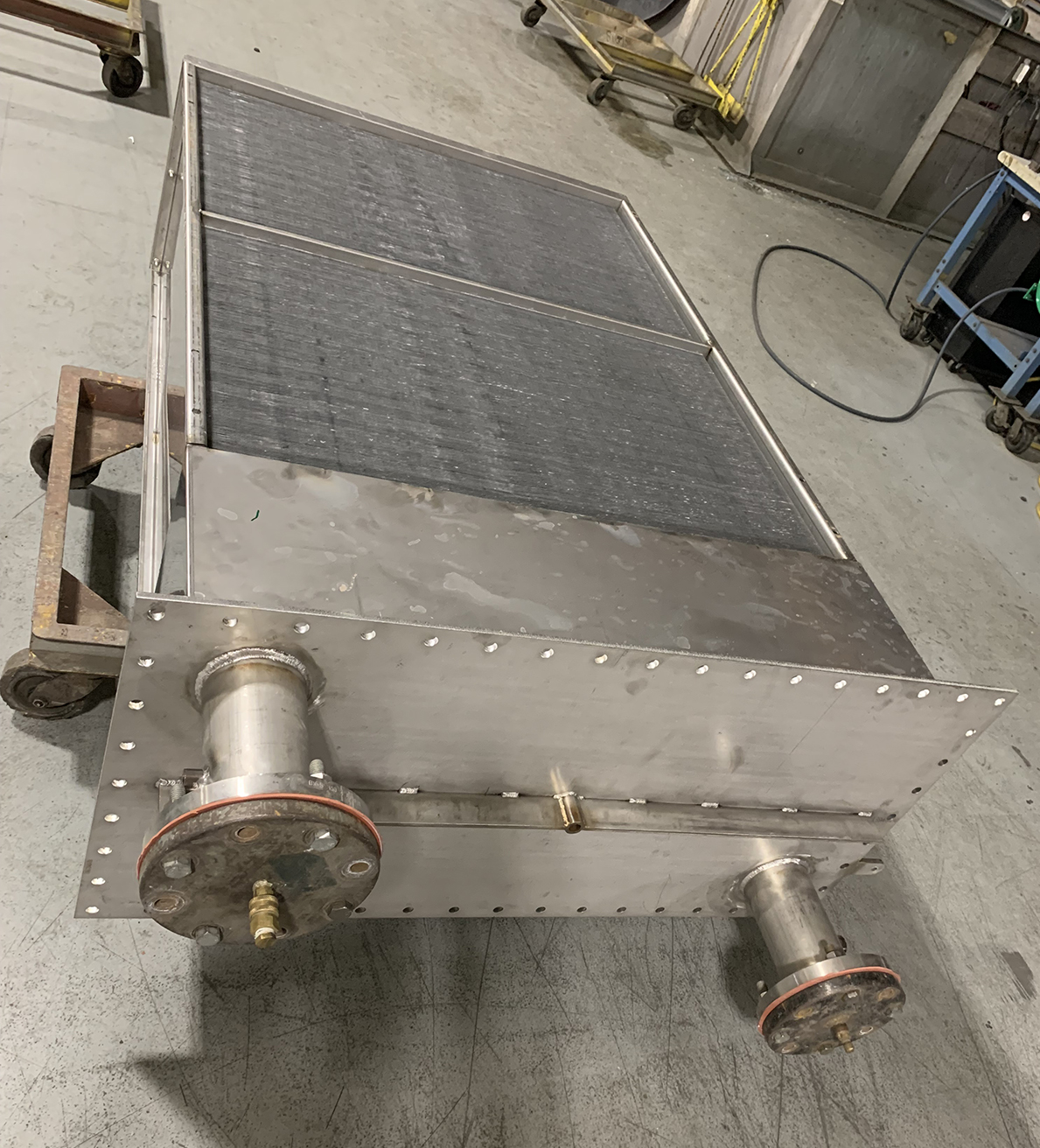

Stainless Steel Airtight Housing

This all stainless steel coil for a specialized industrial process application features 16 rows of stainless steel tubes, special casings and an airtight housing.

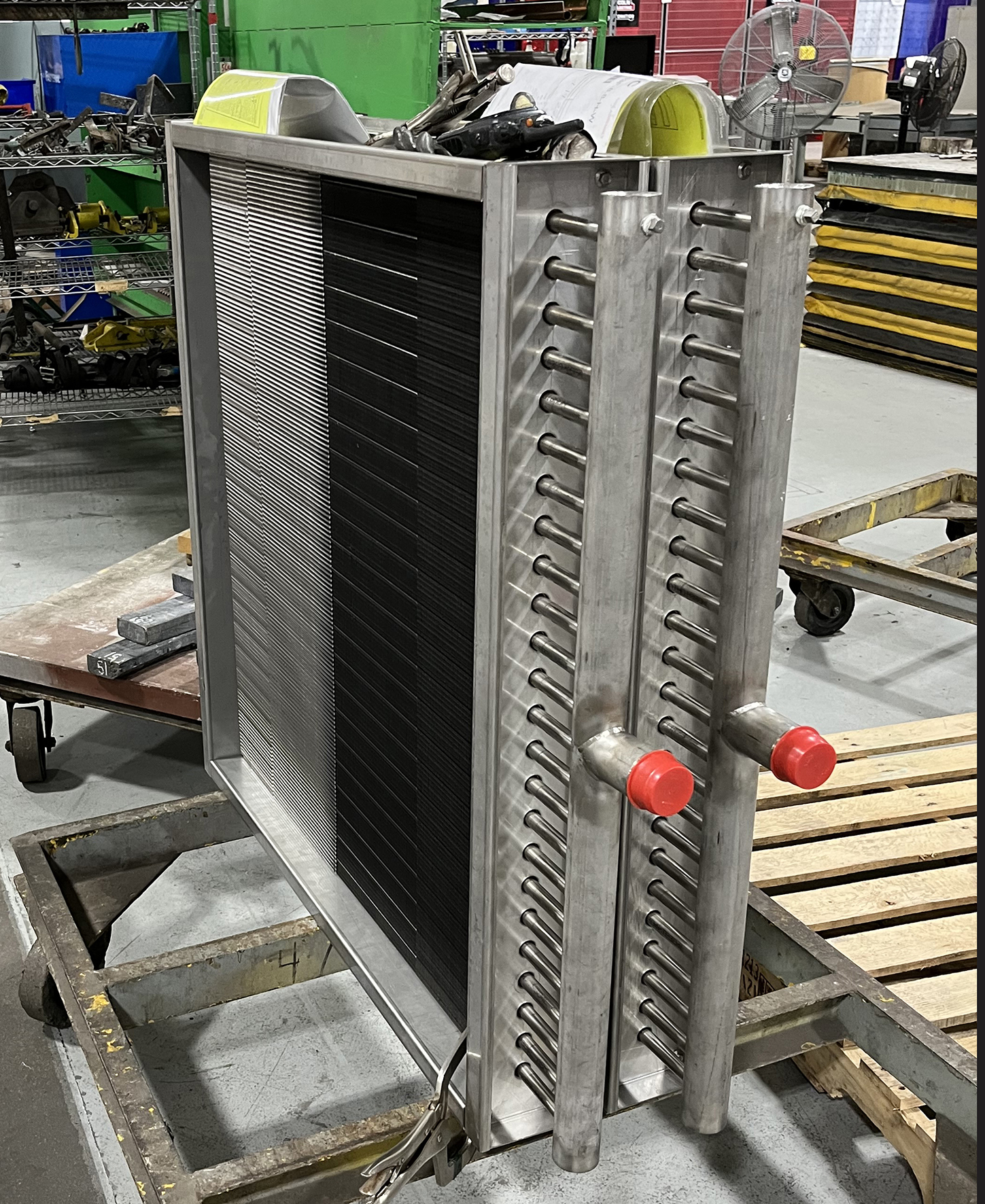

Stacked Pair of Steam Coils

This unique coil is a straight through steam coil (“S” coil) for an industrial process application. It features 5/8” stainless steel tubes which provide a straight-through steam path.

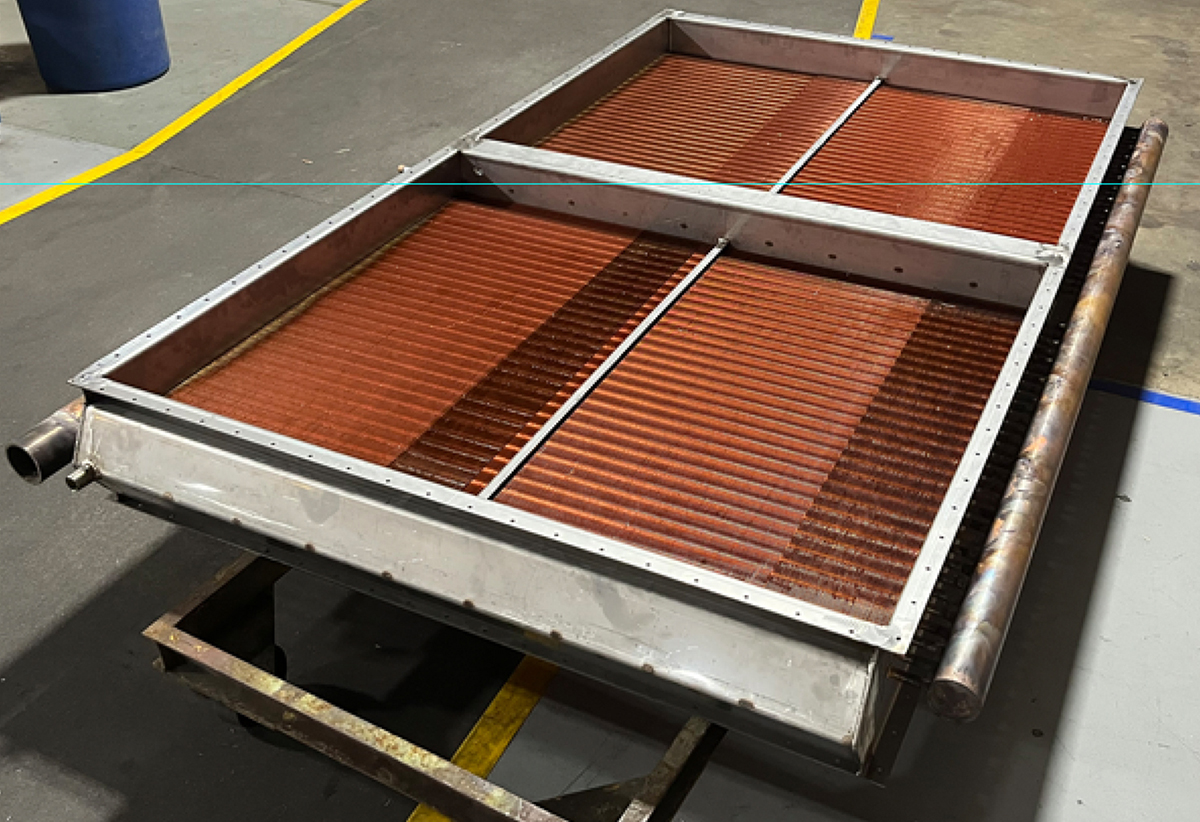

Copper Fin with Integral Drain Pan

This copper fin, dual-pass, single-row coil is a custom engineered solution for a unique customer application. It features an intermediate drain in addition to having a drain pan – all manufactured in a single casing.

High Performance Water Coil

An 8-row single serpentine coil, this product features top and bottom vents and drains, which are stubbed into the header, eliminating “trapped circuits” which prevent the coil from draining and make it more susceptible to freezing.

Turbine Coils

A turbine coil for a gas-fired power plant, this coil optimizes the incoming air temperature and density, allowing the turbine to operate at peak performance – and maximum efficiency – while also preventing freezing in cold weather.

LM6000 Turbine Stacked Coil

This huge turbine inlet coil provides inlet chilling for an LM6000 power generation gas turbine. As air temperature entering a turbine increases, power output decreases. But this coil conditions inlet air to a lower temperature, which increases air density and mass flow rate, returning the turbine’s performance to peak capacity.

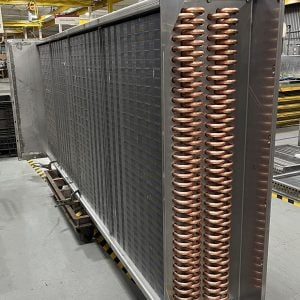

Unique Circuiting

The very unique circuiting of this coil, with a repeating pattern of return bends that are longer than the rest, solved a very specific thermal requirement, while also minimizing the coil’s depth to fit into a smaller space.

Large Stainless Heat Recovery Coil

This very large (about 20 feet long) all stainless steel coil – including stainless tubes, fins and headers – was designed for a high temperature and highly corrosive environment.

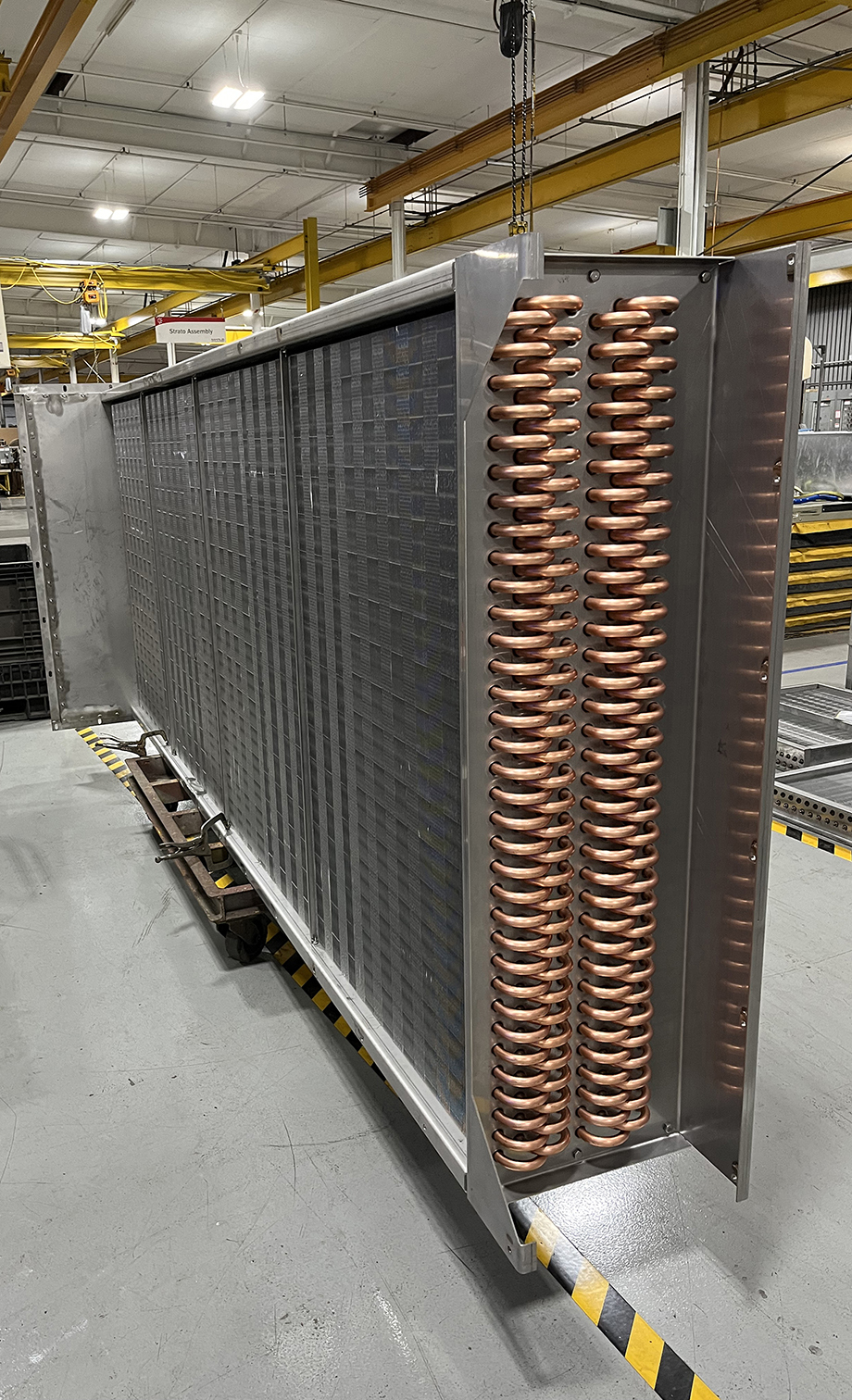

Turbine Inlet Cooling

These three 20 feet long, 7 feet tall turbine inlet coils include several miles of copper tubing! These massive coils are used to treat incoming air in gas-fired power plants.

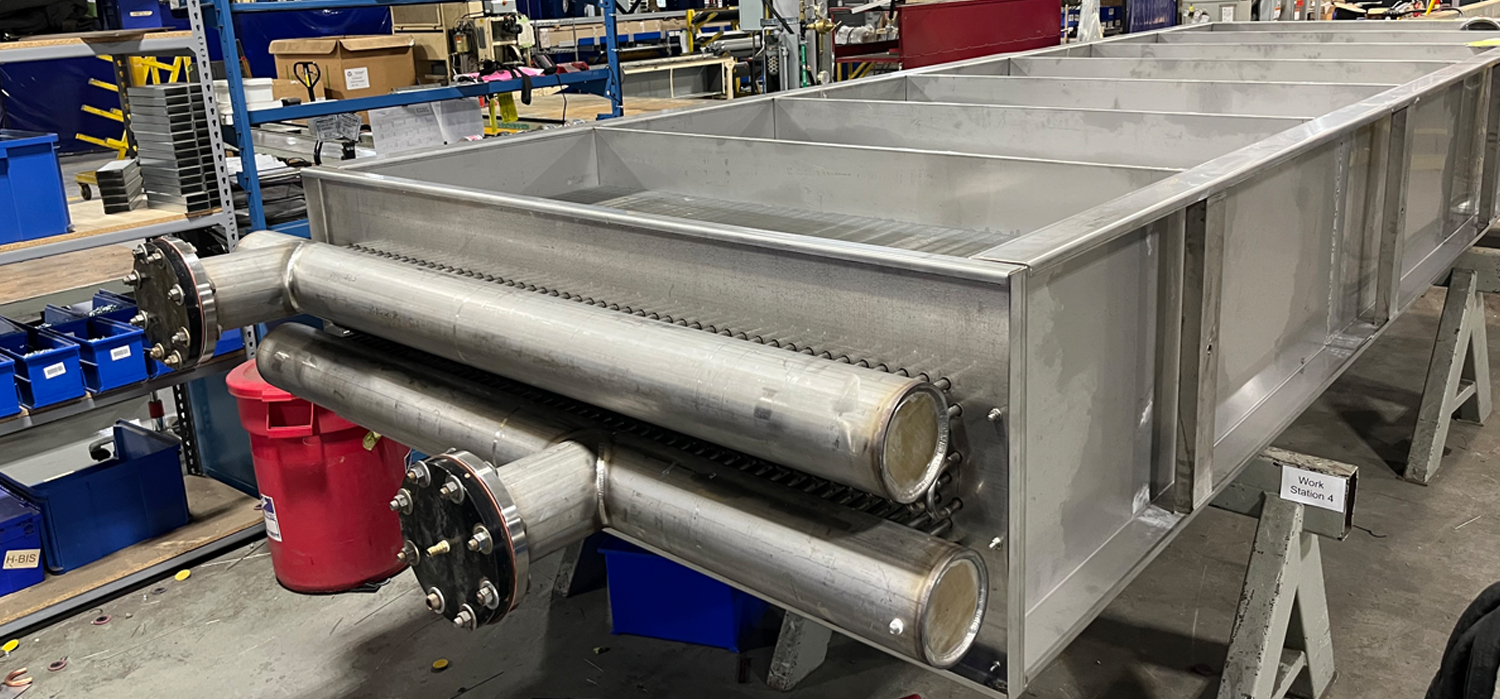

Cleanable Box Header

This coil features a removable box header, allowing access to the tubes for easy inspection and cleaning, which can restore the full performance of the coil over and over again.

Exotic Alloys for Demanding Environments

This coil features copper/nickel tubing for increased corrosion resistance and copper fins. Plus, it has a steel plate on the header side, which will attach to an airtight housing, and a header wrap to prevent air from bypassing the coil face after the housing is installed.