Applications

Aerospace

Aerospace manufacturing environments often require extremely tight tolerances for both temperature control and humidity control, which can be just as precise as the aerospace components being made. That’s why Marlo’s expertise in custom heat transfer solutions is ideal for this demanding industry.

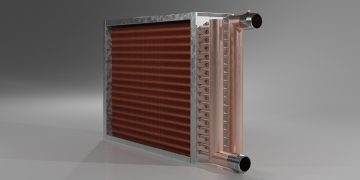

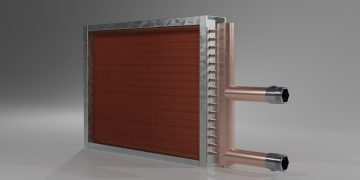

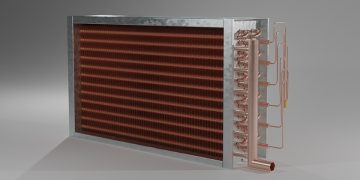

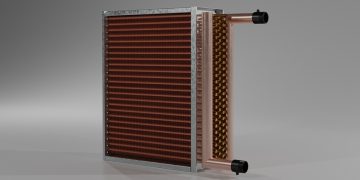

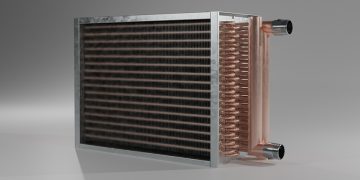

Our custom designed process heating and cooling coils – including hot water coils, steam coils and chilled water coils, as well as those using refrigerants and special fluids – can deliver the specific and consistent temperature and humidity requirements to meet any application need. We have designed and built heating and cooling coils for metrology labs, composite manufacturing, machining centers, special coatings operations and many other aerospace applications.

Automotive

Our extensive automotive experience includes manufacturing process heating and cooling coils for major auto makers, as well as for Tier 1 and Tier 2 suppliers. We specialize in industrial process coils for automotive applications, particularly for paint booths, plating operations and other areas where strict temperature and humidity control must be maintained, or where systems run around the clock in demanding environments.

Many of these coils are built with airtight housings that do not allow cross contamination of airstreams. Our industrial process cooling coils typically use chilled water or various refrigerants, while process heating coils are in most cases steam coils or hot water coils. Of course, our standard commercial coils can also be used for comfort cooling, for both manufacturing and office staff.

Chemical Manufacturing

Because we are a custom manufacturer, we can build each coil component from a wide range of materials, allowing us to choose the metals that will stand up to the often caustic environments and extreme temperatures of chemical applications. For example, we regularly produce process heating and process cooling coils with stainless steel tubes, fins and casings to resist corrosion.

We can also manufacture fins from copper, stainless steel or other metals, rather than the standard aluminum used in typical commercial coils. And when the process air must be isolated from the ambient air in the plant, our process coils can also be made with airtight housings. Whether your chemical processing application includes unique fluids flowing through the coils or toxic gases in the airstream – or both – we can design and build coils to meet your temperature and airflow needs, while withstanding any extreme environment.

Communications

Critical communications facilities require heating and cooling coils that offer maximum reliability. Marlo’s proven ability to deliver this increased dependability and longevity – through things like heavier gauge metals, special materials like stainless steel, and the use of hairpins to minimize brazed joints – has earned us business from critical facilities such as FCC buildings, airport towers, data centers, major telecommunications firms and more.

Our demonstrated reliability in HVAC equipment for the communications industry is further backed by our industry-leading 3-year warranty on every coil and air handling unit we make.

Food Processing

When cleanliness is critical in food and beverage processing applications, Marlo is your best choice for replacement heating and cooling coils. Our experience in these environments includes designing and manufacturing industrial process coils for a wide range of food processing plants, as well as breweries, dairies and other facilities where biologics must be constantly controlled.

We regularly construct coils with antimicrobial and non-corrosive metals like copper and stainless steel, and can even produce all-stainless coils – with stainless steel tubes, fins, headers and casings. These coils offer dependable and long-lasting performance, withstanding frequent washdown with various cleaners and chemicals. We also offer special coatings to meet individual application needs.

Government

Government buildings often have more stringent requirements for HVAC coils and air handling units (AHUs) than typical commercial properties. As shown by our vast experience meeting the heating and cooling needs of the U.S. Navy, Marlo is ready to meet the most demanding government specifications.

Whether you choose Marlo for the high-quality materials we use in our products – including heavier gauge metals than most coil manufacturers – for our many valued industry certifications (including AHRI), or for the industry’s best coil and AHU warranties of 3 full years, you can be sure that you’ll get a product that meets or exceeds your HVAC needs.

Industrial Manufacturing

Name an industrial manufacturing process that requires heating or cooling, and there’s a good chance Marlo has built a process coil for it. Our wide range of experience – over nearly 100 years – means we have seen and solved all types of process heating and cooling challenges in the most demanding environments.

Just a few of these challenges include extreme temperatures, corrosive environments, precise humidity control, tight temperature tolerances, process airstream isolation, special fluid requirements, and many more. With our extensive engineering capabilities and our capacity to manufacture with a wide range of materials – copper, aluminum, steel, galvanized, stainless steel, copper nickel and more – we can deliver a solution to any process heating or process cooling need.

Institutional

Because institutional buildings are designed to last much longer than traditional commercial facilities, they typically have more stringent requirements for both HVAC coils and air handling units (AHUs). That’s why Marlo products – which are engineered and built for life – are ideal for these demanding applications.

With our higher level of quality, which can include heavy wall tubing, special materials, heavy gauge metals and more, Marlo coils and AHUs are perfect for institutional buildings that have long life expectancies. Our heating and cooling coils can be AHRI certified to prove performance, and all Marlo products are backed by our 3-year warranty (in an industry where most manufacturer’s warranties are only one year).

Maritime

Marlo is the premiere manufacturer of air handling units, heating coils and cooling coils for maritime environments, due in large part to our vast experience building these products for the U.S. Navy. Shipboard coils, in particular, require additional features not found in land-based applications, such as the ability to minimize condensate carryover when the coils are tilted to severe levels (as often happens in rough seas).

Maritime applications also require resistance to salty environments, which often means special coatings and/or corrosion-resistant materials such as copper or copper nickel for fins and tubes. In addition, both coils and AHUs on vessels require resistance to the vibrations produced by engines, as well as impacts produced by rough seas. Again, our long history with the Navy gives Marlo unmatched experience producing HVAC products capable of surviving the most extreme marine environments.

Medical Facilities

Healthcare buildings – including medical offices, hospitals, urgent care centers, surgery centers and many others – often have washdown requirements for heating and cooling coils (which can include caustic cleaning fluids) that are not found in typical commercial buildings. This requires special coil materials and/or coatings not offered by typical commercial coil manufacturers.

UV lights, now common in medical applications for their antimicrobial properties, present additional challenges to coating longevity. However, Marlo is well versed in meeting the needs of the healthcare industry, and can help select the right coil materials and coatings for these demanding applications. When it comes to HVAC coils for medical facilities, Marlo is just what the doctor ordered for performance and reliability.

Office Buildings

Office buildings come in all shapes and sizes, with all types of unique HVAC systems and challenges. But whatever the building, Marlo can meet its heating or cooling coil needs, because every coil and air handling unit (AHU) we make is built to order. That means we can create an exact replacement for virtually any existing office building coil, or customize a MarloAIR AHU to meeting the building’s exact heating and cooling needs.

Our MarloMetrics® selection software tool can create an infinite number of arrangements to make sure your replacement coil fits and performs exactly as intended. For a complete AHU, we also have our AHU Metrics software to assure the unit is customized specifically for your building. Our experts can match your current equipment or offer improved performance to meet changing needs – such as increased capacity due to higher heat loads, or reduced air restriction to improve fan efficiency and lower your energy costs.

Pharmaceutical Manufacturing

Pharmaceutical production facilities often have a number of special requirements when it comes to process heating coils and process cooling coils. In many cases, cross contamination of airstreams must be eliminated, making our airtight coil housings an ideal solution. To address antimicrobial needs, we can also produce coil fins and tubes from stainless steel, copper and other specialty metals.

Coils in pharma applications often have stringent washdown requirements, which can include corrosive cleaning fluids, calling for corrosion-resistant materials and coatings that Marlo provides on a regular basis. Plus, we can offer solutions to UV lights, which are often found in pharmaceutical facilities and can create issues with coating longevity. Whatever challenges your pharmaceutical application faces, Marlo can provide the solutions.

Power and Energy

Energy applications typically require massive coils, and Marlo regularly builds coils 30 feet long and longer. We specialize in turbine inlet coils used for heating or cooling the air entering high performance land-based gas turbines. In addition to other benefits, turbine inlet heating coils protect against freezing, while turbine inlet cooling coils improve the power output of the turbine.

Gas turbine inlet coils also require the ability to minimize Foreign Object Damage (FOD), so our coils are designed with features that prevent objects from entering and damaging expensive turbines. Additional power and energy applications we serve include heat recovery systems, economizers to maximize efficiency, coils for high sediment environments such as cooling ponds or river water, and more. Plus, we have produced thousands of coils for nuclear reactor containment areas and balance of plant applications.

Pulp and Paper

Pulp and paper plants typically use steam coils for process heating, requiring very high temperatures. Marlo has extensive experience serving the needs of these facilities, with both straight-through steam coils and distributing steam coils. Our custom designed and built steam coils can address a very wide range of steam quality, pressures and temperatures.

In addition, these applications often call for coils that can withstand frequent cleaning and/or require wide fin spacing to minimize downtime due to cleaning needs. Because all of our heating and cooling coils are custom built – never “off the shelf” – we can accommodate these and any other unique needs, using a wide range of materials and coatings.

Schools/Universities

Large educational facilities that have central plant cooling and heating are a Marlo specialty. Both our coils and our air handling units (AHUs) can be custom built to meet the more stringent HVAC requirements – and longevity needs – of most schools and universities. As with other applications where buildings are expected to last for many decades, our products can be made with heavier, stronger materials for extended durability.

In addition to coils and AHUs, our Stratomizer line is especially well suited to schools and universities during winter months in cooler climates, helping to meet fresh air requirements (for student and staff safety). The Stratomizer, an integral face and bypass (IFB) coil, can bring in fresh outside air – efficiently and cost-effectively – regardless of outside air temperatures, while also providing maximum coil freeze protection.

Semiconductor Manufacturing

Semiconductor plants often require strict temperature and humidity control – which is no problem for the Marlo engineering and manufacturing team. Our heating and cooling coils can meet these needs, as well as any other special requirements of these typically very clean environments.

Our airtight coil housings are often used in chip manufacturing to prevent the cross contamination of airstreams. Marlo coils can also be designed to meet washdown requirements, and can be built with materials that withstand harsh cleaning fluids. We can help identify the materials and/or coatings to address these needs, and deliver coils that meet your performance specifications.