Marlo is the industry leader in serving the very unique heat transfer needs and stringent requirements of the power generation industry, specifically at gas-fired power plants.

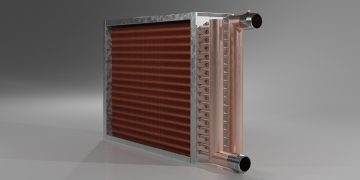

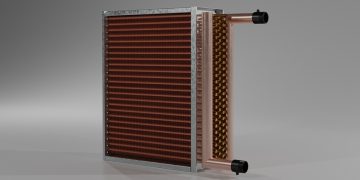

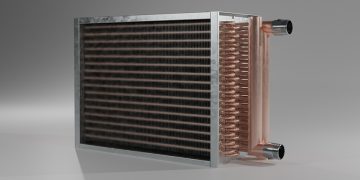

For this critical industry, we custom build massive heating and cooling coils – commonly up to 30 feet long and 8 feet tall – to treat air entering gas turbines ranging in size from 20MW to over 500MW.

Over many years, we have worked closely with major system suppliers and turbine manufacturers to create coils that are manufactured to the strictest quality standards to meet the demands of these challenging environments. Our turbine coils are approved by all major turbine OEMs, are installed at power generation plants around the world, and have performed under very extreme conditions while demonstrating performance, durability and reliability.

Depending on the individual application and climate, our turbine inlet coils can help increase power output, eliminate icing, minimize pressure drop, boost efficiency and improve reliability – contributing to a more resilient and dependable power grid that helps meet growing worldwide demand.

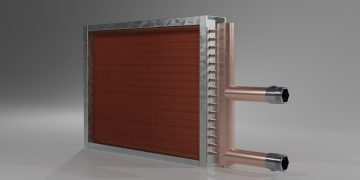

Turbine Inlet Cooling Coils

The power output of a gas turbine is inversely related to the inlet air temperature, so lowering the temperature of the incoming air increases the power output. Marlo turbine inlet cooling coils condition the incoming air to a lower temperature, which increases air density and mass flow rate, restoring the performance of the turbine to its peak capacity regardless of the ambient temperature, humidity and availability of water.

The cooling coils allow the plant to recover the power output lost due to high temperatures regardless of relative humidity. This recovered power eliminates the need for additional power generation support and helps to meet the demand of the local community.

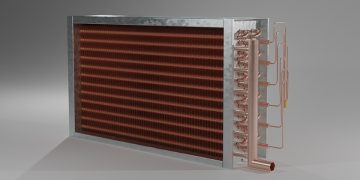

Turbine Inlet Heating Coils

Marlo turbine inlet heating coils can improve the efficiency of gas turbines in turn down situations and reduce the possibility of icing – insuring the plant against turbine damage, expensive repairs and lost revenue. In cooler climates, humid air can cause ice formations that can damage a turbine and negatively affect its performance. If carried into the turbine intake, ice crystals can damage turbine blades, leading to extensive downtime and costly repairs.

In addition to the anti-icing function, Marlo turbine heating coils are used to increase the temperature of incoming turbine air, which in turn increases the efficiency of the gas turbine in turn down operation when full capacity of the turbine is not required. This situation continues to be more and more prevalent with the increased use of supplemental renewable energy sources such as wind and solar.

More Products

Related News

Contact

For any further information or to request a quote